|

|||

|

|

|||

|

Page Title:

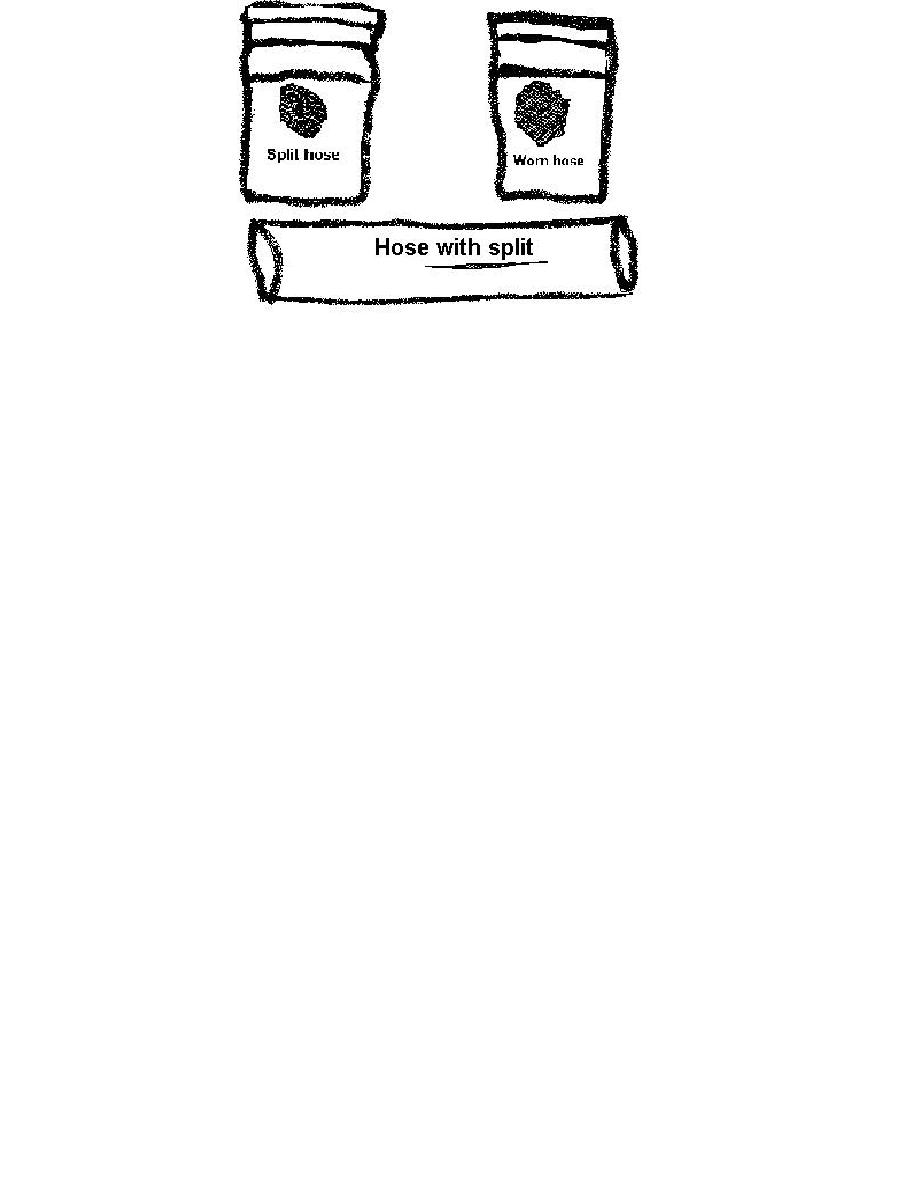

Figure 3-5. Examples of defective air hose |

|

||

| ||||||||||

|

|  Figure 3-5. Examples of defective air hose.

(7) Engine coolant level. The engine coolant level shall be checked and filled if necessary.

(8) Hand Brake Tests. The engineer shall check the operation of the hand brake.

(9) Engine protective devices. If so equipped, the low water button, oil pressure reset

button, and engine overspeed lever shall be checked. All inspection covers shall be checked for

proper fit.

(10) Air and fuel oil cleaners and filters. Air and fuel oil cleaners and filters shall be

visually checked for contamination.

(11) Couplers and knuckles. The couplers at each end of the locomotive shall be checked

for any visible flaws, and the presence of knuckles and knuckle pins shall be confirmed.

(12) Wheels, sanders, brake rigging, and other truck components. The wheels shall be

visually checked for any obvious defects such as missing metal, large flat spots, thin or high

flanges, or plate discoloration. See Figures 3-6 to 3-7 for examples of wheel defects. The

sanders shall be checked to see that they are properly aimed and not damaged. The brake rigging

shall be checked for integrity and the shoes checked for adequate wear remaining. The rest of the

truck shall be checked for any obvious defects such as missing springs, cracked frame, or loose or

dragging components.

(13) Fuel oil tank. Check the fuel oil level and check the fuel oil tank for leaks.

3 - 13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |